BOSCH L-Jetronic Injection Manual.PDF Author: Crit Keywords: Bosch L-Jetronic L Jetronic RX-7 Brought to you by the team at VintageRotaries.org Created Date. Problem: Jetronic controls fuel supply while the electronic ignition system provides optimal ignition control. Motronic combines the two systems. A computer controls the injection and ignition systems with reference to shared optimization criteria. Digital data processing and micro-processors make it possible to trans-late extensive operating.

- Bosch Mono Jetronic Manual Seadart Author: oa-uat.fableandmane.com-2021-06-22T00:00:00+00:01 Subject: Bosch Mono Jetronic Manual Seadart Keywords: bosch, mono, jetronic, manual, seadart Created Date: 6/22/2021 10:42:07 PM.

- Wait for some minutes until the download Bosch Mono Jetronic Manual PDF ePub is finish. This soft file Bosch Mono Jetronic Manual PDF ePub is ready to read anytime you want. Get Bosch Mono Jetronic Manual PDF ePub and save both time and money by visit our website, available in formats PDF, Kindle, ePub, iTunes and Mobi also.

- Title: Repair manual bosch mono jetronic, Author: PaulaWood2020, Name: Repair manual bosch mono jetronic, Length: 4 pages, Page: 1, Published: 2017-09-20 Issuu Search and overview.

The single injector of the Mono-Jetronic system, Fig. 12.34, like that of the GM Rochester TBI system, Fig. 12.36, injects intermittently into the air intake, just above the throttle valve. A rotary, virtually pulse-free, electric pump in the fuel tank delivers at a pressure of 1 kN/m2 through a fine filter

1 Electric fuel pump

2 Tank

3 Filter

4 Air temperature sensor

5 Single point injector

6 Pressure regulator

7 Electronic control unit

8 Throttle valve actuator

9 Throttle valve potentiometer

10 Lambda sensor

11 Engine temperature sensor

Bosch Mono Jetronic Manual Instructions

12 Ignition distributor

13 Battery

14 ignition and starter switch

1 Electric fuel pump

2 Tank

3 Filter

4 Air temperature sensor

Bosch Mono Jetronic Manual Model

5 Single point injector

6 Pressure regulator

Bosch Ke Jetronic Systems

7 Electronic control unit

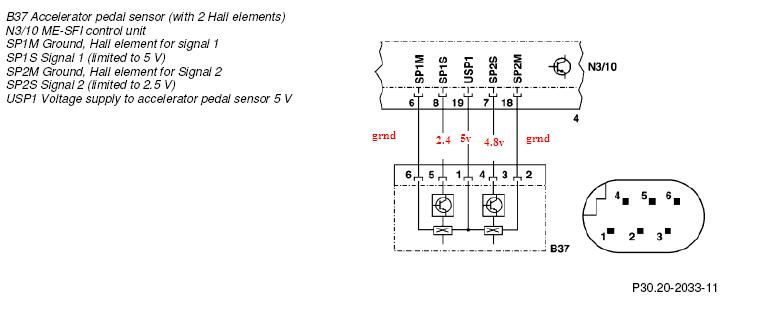

Fig. 12.34 The diagram issued by Bosch to injection system

8 Throttle valve actuator

9 Throttle valve potentiometer

10 Lambda sensor

11 Engine temperature sensor

12 Ignition distributor

13 Battery

14 ignition and starter switch illustrate their Mono-Jetronic single-point to the injector. By virtue of its low output pressure, this pump is both light and very economical to manufacture, many of its components being of plastics.

The spray pattern is such that two jets are delivered, Fig. 12.35, one into each of the crescent-shaped gaps between the edges of the throttle valve and its cylindrical housing. Fine atomisation ensures that, even with the throttle wide open, the mixture distribution is homogeneous. Fuel in excess of requirements is returned to the tank, the continuity of supply preventing formation of vapour locks. Each injection is triggered synchronously by the ignition system and is timed to continue for periods of from 1 ms upwards, according to the quantity of fuel needed.

The input to the electronic controller includes signals of engine speed (from the ignition distributor), throttle valve position, and engine air intake temperatures. Stored in its memory is the information it needs for use, in association with the input signals, for calculating the time the injector is required to remain open for supplying the quantity of fuel appropriate for efficient operation of the engine.

The controller is programmed to enrich the mixture for cold starting, warm-up and acceleration. In response to signals from the various electric circuits, the engine temperature and speed sensors, an electric motor adjusts

Electric connection

Electric connection

Coil

Coil

I Fuel return

I Fuel supply

Fig. 12.35 Bosch low-pressure injector with twin jets for injecting the spray into the two crescent-shaped openings on each side of the throttle valve as it opens

I Fuel return

I Fuel supply

Fig. 12.35 Bosch low-pressure injector with twin jets for injecting the spray into the two crescent-shaped openings on each side of the throttle valve as it opens the position of the throttle stop to set the idle speed at an appropriately low level, regardless of what loads are switched in or out. As a contribution to fuel economy and reduction of emissions a fuel cut-off operates the idling system in the overrun condition and, if required in any particular application, at maximum engine speed. Compensation is effected for variations in the voltage of the output from the battery.

Continue reading here: 1224 The GM Multec singlepoint system

Was this article helpful?